Downloads

Training

Downloads

The perfect way to stay connected!

Power Cable Terminations

We take pride in our extensive experience in manufacturing high-quality joints for medium voltage cables. Our cutting-edge technology in heat shrink and cold applied joints allow for highly-customized solutions, resulting in significant cost savings for our clients.

Enhanced Durability

Field Proven Technology

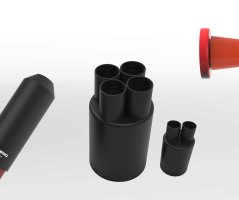

Heat Shrink

- Cable Joints & Terminations

Pre Moulded

- Cable Joints & Terminations Moulded Components

Cold Shrink

- Cable Joints & Terminations Screened Separable Connectors

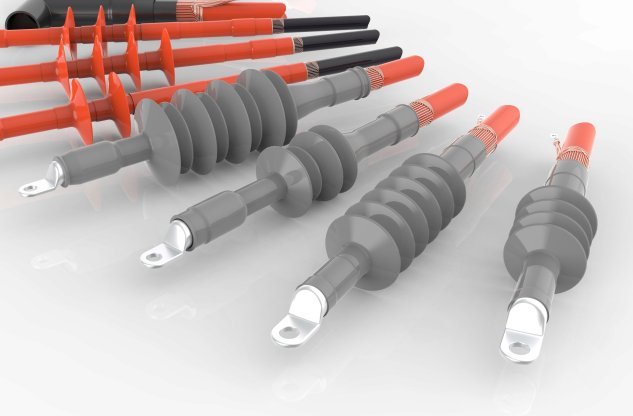

Compaq Medium Voltage Cable Terminations

Medium voltage termination ensure hassle-free connectivity in any given scenario, without requiring any maintenance. In order to ensure the proper connection for medium voltage cable terminations to various equipment, such as air-insulated switchgear, transformers, overhead lines or busbars, it is crucial to select the appropriate type of MV cable termination.

LOOK NO FURTHER! We offer an exceptional variety of high-quality MV cable terminations that cater to both indoor and outdoor applications. These top-notch products come in various options suitable for different system voltages and are available in an array of state-of-the-art technologies such as heat shrink, cold shrink, or pre-moulded push on type. So, rest assured, your perfect termination solution is just a click away!

Heat Shrink Terminations

For over two decades, engineers in the utility and industrial sectors have trusted Compaq's heat shrink terminations for their outstanding reliability and long-term performance. Renowned for their reliability, our terminations are the preferred choice for distribution voltages up to 66 kV. Discover why Compaq's cable terminations set the standard in the industry.

Cold Shrink Terminations

Our medium voltage cable terminations incorporate state-of-the-art cold-shrink technology, providing unmatched safety, reliability, and ease of installation—benefits that are highly valued by professionals. Whether you need MV cable terminations for indoor or outdoor applications, we offer an exceptional range of products to meet your requirements, including options suitable for a wide range of system voltages.

Pre Moulded (Push On) Terminations

At Compaq, we take pride in our Pre-Moulded (Push On) terminations technology, which forms the foundation of our development in this area. Our team has dedicated significant effort to optimizing the materials used in our terminations, focusing on its product design, functionality, and suitability for manufacturing and expected service environments. Our high-quality silicone rubber termination body is chosen specifically for its superior mechanical, hydrophobic, non-tracking, and insulating properties. Plus, the stress control cone is conveniently integrated right into the termination.

Don't see what you're looking for?

Our team of experts is here to help! Contact us today to discuss your specific project requirements

and find the perfect solution for your needs.